How to Remove an Airlock from Tractor?

Ever had your tractor come to a sudden stop while working in the field? Chances are, you’ve encountered an engine air-lock. This frustrating problem occurs when air gets into the fuel system, interrupting the flow of fuel and causing the engine to shut down. If you’re a tractor owner, especially of a Massey Ferguson Tractor, knowing how to deal with an air-locked engine is essential for smooth agricultural operations.

What is Engine AirLock in Tractor?

So, what exactly is engine air-lock? Simply put, it’s when air infiltrates the fuel system, leading to fuel flow interruption and engine shutdown. This typically happens in diesel engines and can bring your tractor to a halt at the most inconvenient times.

Why does Airlock happen in Diesel Engines?

Understanding what causes air-lock is the first step in preventing it. Here are the major culprits:

Empty Diesel Tank

Running your diesel tank too low is a recipe for disaster. Always ensure your tank is not only filled but has a comfortable reserve to avoid air-lock.

Diesel Stop-Cock Issues

The diesel stop-cock should always be fully open to ensure an uninterrupted fuel flow. A partially open or closed stop-cock can cause air-lock.

Choked or Closed Fuel Filters

Fuel filters are crucial in keeping your fuel clean. If they get clogged or closed, it can lead to air entering the system.

Loose Connections

Loose fuel pipes, nuts, and bolts can create gaps for air to sneak into the fuel system. Regularly check and tighten all connections to prevent this.

What are Signs of an Air-Locked Engine?

How can you tell if your engine is air-locked? Look out for these signs:

- Difficulty in starting the engine

- Engine stalling or abrupt shutdowns

Preventive Measures

Prevention is better than cure. Here’s how you can avoid engine air-lock:

Regular Fuel System Checks

Regularly inspect your fuel system to ensure everything is in working order.

Maintaining Proper Fuel Levels

Never let your fuel tank run too low. Keep it filled with a comfortable reserve.

Ensuring Tight Connections

Regularly check and tighten all fuel system connections to prevent air from entering.

Step-by-Step Guide to Remove Air-Lock

If you do encounter air-lock, here’s a step-by-step guide to remove it:

Ensuring Secure Fuel System Connections

First, make sure all pipes and nuts in the fuel system are securely tightened.

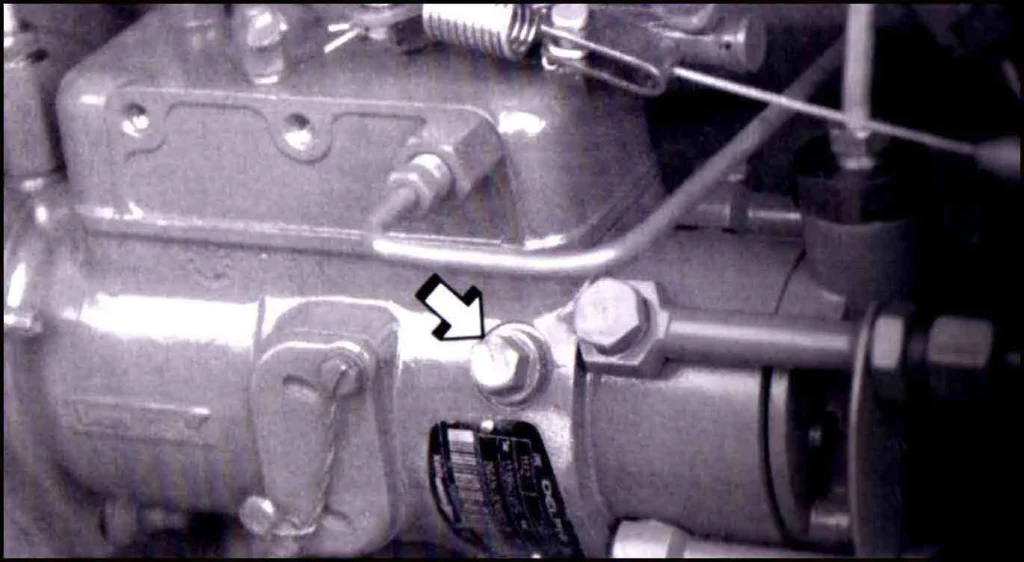

Initiating Smooth Diesel Flow

Open the upper vent plug of the primary fuel filter and pump the fuel lift lever to get the diesel flowing smoothly. Close the vent plug once the air is expelled.

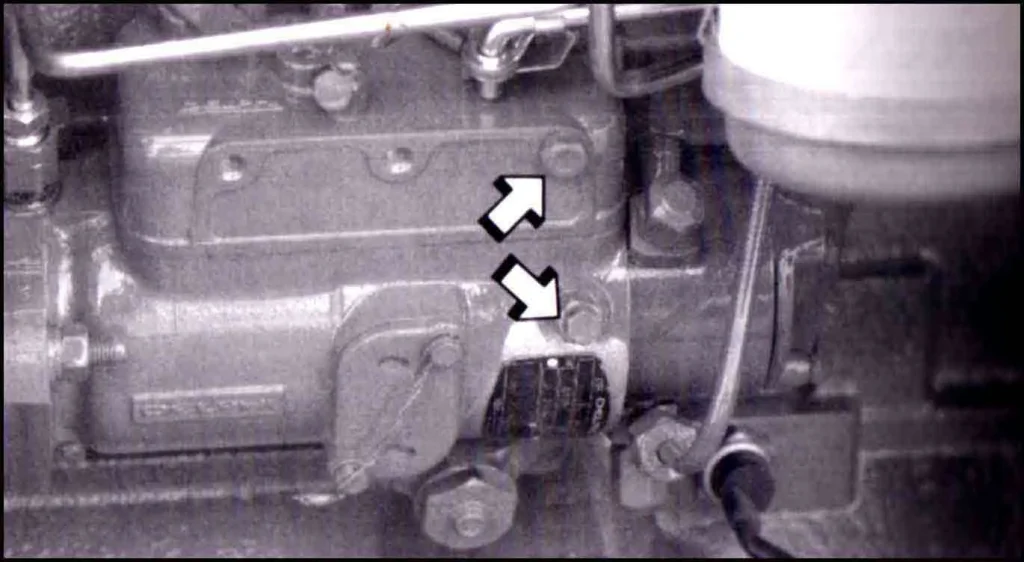

Optimizing the Fuel Injection Pump

Loosen the screws on the fuel injection pump and move the priming lever until diesel flows out without air bubbles. Tighten the lower screw first, then the upper one.

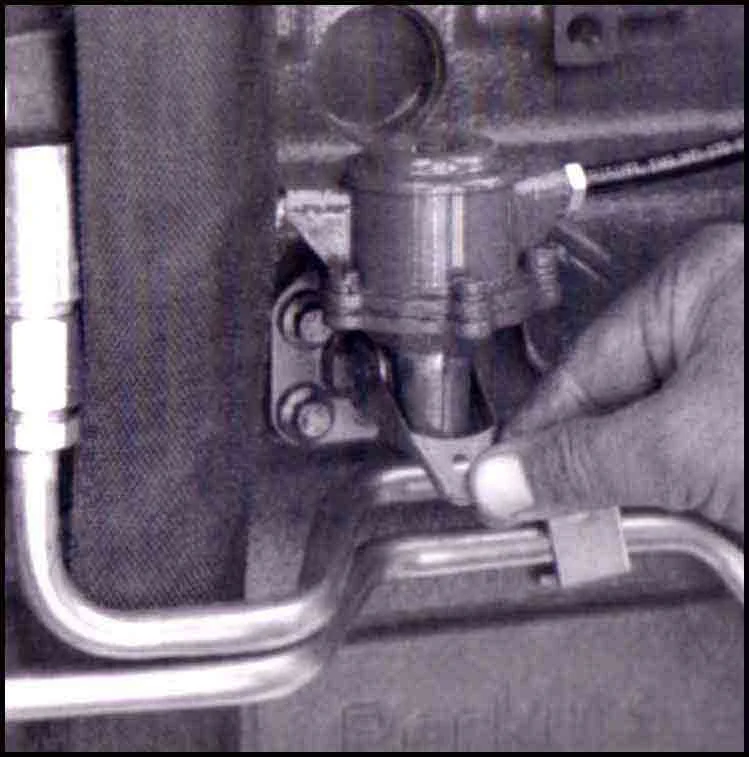

High-Pressure Pump Adjustment

Loosen the high-pressure pump of the cylinder’s atomizer and start the tractor. As the engine sound stabilizes, tighten the high-pressure pipe.

Tools Needed for Air-Lock Removal

Here are the tools you’ll need:

- Wrench set

- Screwdrivers

- Fuel lift lever

- Priming lever

Tips for Using Each Tool Effectively

- Use the right size wrench to avoid damaging nuts and bolts.

- Handle screwdrivers with care to avoid stripping screws.

- Operate the fuel lift and priming levers smoothly to ensure proper fuel flow.

Common Mistakes to Avoid while Removing an Airlock from Tractor Engine

When dealing with air-lock, avoid these mistakes:

Overlooking Small Leaks

Even small leaks can let air into the system. Always address them promptly.

Ignoring Regular Maintenance

Regular maintenance is crucial. Skipping it can lead to bigger problems down the line.

Troubleshooting Persistent Issues

If the air-lock issue persists, try these steps:

- Recheck all connections for tightness.

- Ensure there are no blockages in the fuel lines.

- Consider seeking professional help if the problem continues.

Tips for Long-Term Maintenance

To keep your tractor in top shape, follow these tips:

Importance of Regular Checks

Regularly inspect your fuel system and connections.

Keeping a Maintenance Log

Maintain a log of all checks and repairs for future reference.

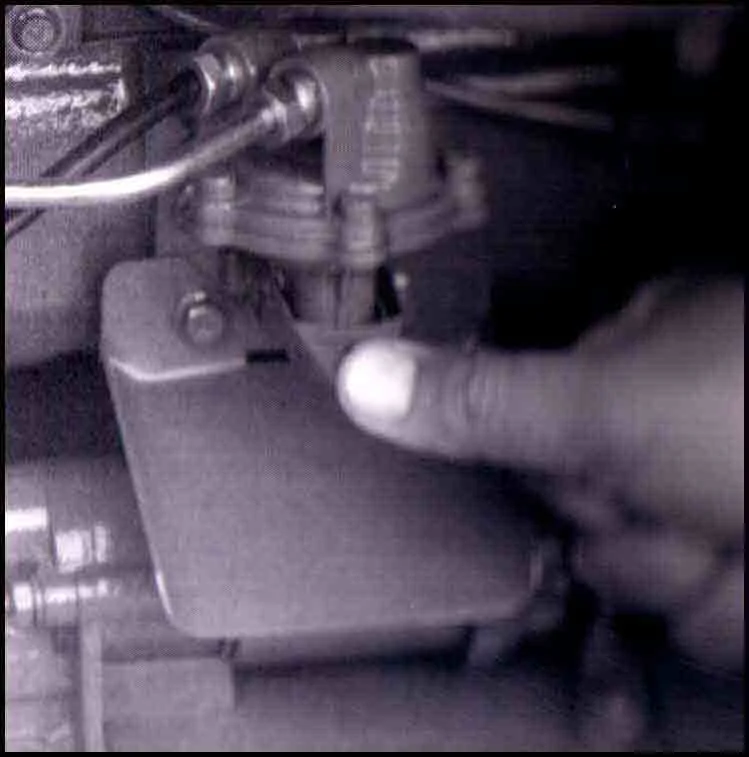

HAND PRIMING PUMP LEVER MF 375/ MF 385 / MF 385 4WD

FAQs

Air-lock can be caused by an empty fuel tank, clogged filters, loose connections, or issues with the diesel stop-cock.

Regular maintenance, keeping your fuel tank adequately filled, and ensuring tight connections can prevent air-lock.

You’ll need a wrench set, screwdrivers, a fuel lift lever, and a priming lever.

Signs include difficulty starting the engine and abrupt engine shutdowns.

If you’ve followed all troubleshooting steps and the problem persists, it’s time to seek professional assistance.