Most Common Massey Ferguson 385 Tractor Problems and Solutions

If you’re a farmer or someone who deals with farm machinery, you’ve probably heard of the Massey Ferguson 385 Tractor. This tractor model is known for its reliability and power, making it a favorite among many in the agricultural sector. Whether you are plowing fields, planting crops, or hauling heavy loads, the Massey Ferguson 385 can handle it all. Its robust build and efficient performance make it a valuable asset on any farm. However, even the best machines can encounter problems, and the Massey Ferguson 385 is no exception.

No doubt, brand-new Massey Ferguson tractors have many strengths. However, like any piece of machinery, this Massey Ferguson model also has its fair share of issues. These problems can range from starting difficulties to more complex hydraulic and transmission issues. Farmers often face these challenges, which can disrupt their operations and cause unnecessary downtime. Understanding these common problems is the first step in preventing them from occurring and ensuring your tractor remains in top working condition.

This blog dives into the most common problems encountered with MF 385 2WD/ MF 385 4WD. From starting issues, where the tractor struggles to turn on, especially in colder weather, to overheating problems that can cause significant damage if not addressed promptly, we cover it all. We also explore hydraulic system malfunctions that affect the performance of farm implements and lifting capabilities, as well as transmission troubles that make gear shifting a hassle. Electrical issues that impact essential components like lights and gauges are also discussed in detail.

By understanding and addressing these common problems, you can significantly extend the life of your Massey Ferguson 385 tractor. Regular maintenance and timely repairs will keep it running efficiently, saving you time and money in the long run. So, whether you’re a seasoned farmer or new to the agricultural world, this blog provides valuable insights to help you maintain your tractor and keep your farming operations running smoothly.

STARTING ISSUES

Problem: Difficulty Starting, especially in Cold Weather

Solution:

- Battery Inspection: Make sure the battery is fully charged and in good condition. Replace if needed.

- Starter Motor Check: Examine the starter motor for any signs of wear or damage. Repair or replace if required.

- Glow Plug Functionality: Verify that the glow plugs are working properly. Replace any defective ones.

- Fuel System Maintenance: Inspect the fuel lines for blockages and ensure the fuel filter is clean to maintain smooth fuel flow.

OVERHEATING

Problem: Engine Overheating

Solution:

- Coolant Levels: Regularly monitor and refill coolant as needed to prevent overheating.

- Radiator Maintenance: Keep the radiator clean and free from debris; flush it if necessary to ensure optimal performance.

- Thermostat Check: Test the thermostat to confirm it functions correctly. Replace it if faulty.

- Water Pump Inspection: Examine the water pump for leaks or damage and replace it if required.

HYDRAULIC SYSTEM ISSUES

Problem: Hydraulic System Malfunction

Solution:

- Hydraulic Fluid Check: Ensure the hydraulic fluid is at the proper level and use the recommended type for optimal performance.

- Filter Replacement: Regularly change the hydraulic filters to prevent blockages and maintain efficiency.

- Line Inspection: Examine hydraulic lines for leaks or damage, and replace any faulty sections.

- Pump Assessment: Test the hydraulic pump to confirm it generates adequate pressure; replace if necessary.

TRASMISSION PROBLEMS

Problem: Transmission Issues – Difficulty Shifting Gears or Unusual Noises

Solution:

- Transmission Fluid Check: Ensure the transmission fluid is at the correct level and in good condition. Refill or replace if contaminated.

- Clutch Adjustment: Verify that the clutch is properly adjusted to allow smooth gear shifts. Make necessary adjustments.

- Gear Linkage Inspection: Examine the gear linkage for signs of wear or damage. Repair or replace any faulty components.

- Bearing Assessment: Check transmission bearings for wear or damage and replace them if necessary.

ELECTRICAL ISSUES

Problem: Electrical Components Not Working

Solution:

- Fuse Inspection: Check for blown fuses and replace them as needed.

- Wiring Examination: Inspect the wiring harness for any damage or corrosion. Repair or replace faulty wires.

- Alternator Testing: Ensure the alternator is properly charging the battery. Replace if defective.

- Connection Check: Verify that all electrical connections are clean and secure.

FUEL SYSTEM PROBLEMS

Problem: Fuel System Malfunctions – Engine Stalling or Loss of Power

Solution:

- Fuel Filter Maintenance: Regularly replace fuel filters to prevent clogging.

- Fuel Line Inspection: Look for leaks or blockages in the fuel lines and clean or replace as necessary.

- Fuel Pump Testing: Check if the fuel pump is operating correctly. Replace if it fails to deliver fuel efficiently.

- Injector Cleaning: Clean or replace clogged or malfunctioning fuel injectors.

- Sometimes removing an airlock also resolves these sort of issues.

BRAKE ISSUES

Problem: Brake Problems – Ineffective Braking or Brake Failure

Solution:

- Brake Pad Check: Inspect the brake pads for wear and replace them if needed.

- Brake Fluid Monitoring: Ensure the brake fluid is at the proper level and top up if required.

- Brake Line Examination: Look for leaks or damage in the brake lines and repair or replace as necessary.

- Brake Drum Maintenance: Keep brake drums clean and free from debris to ensure proper braking performance

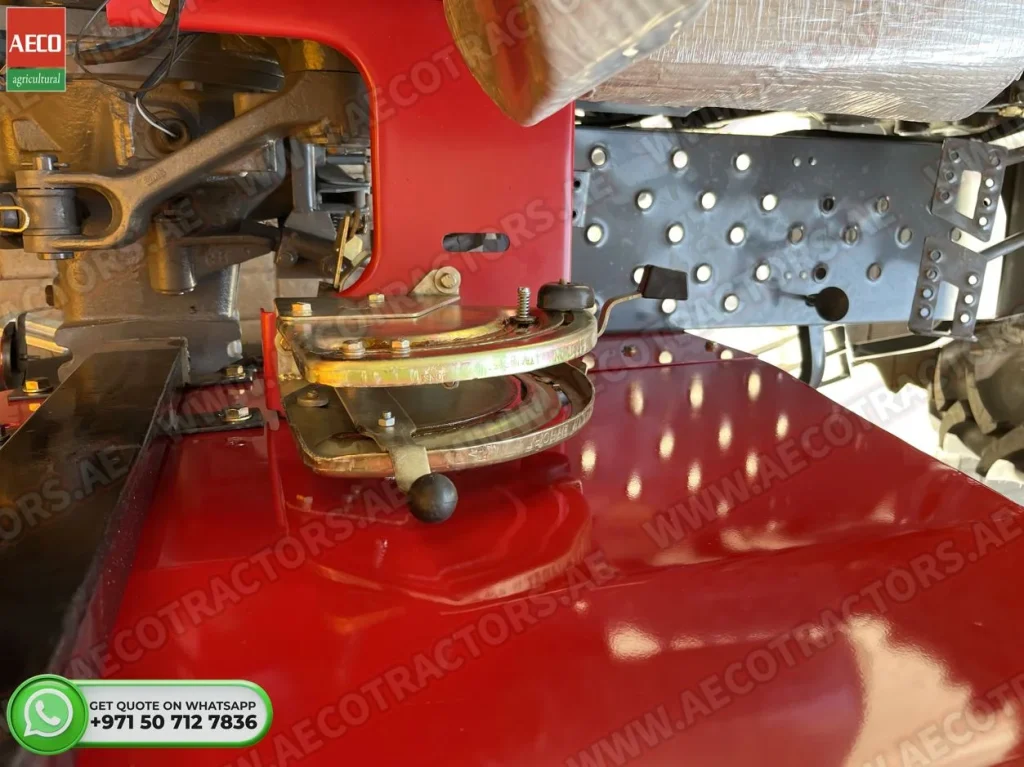

PTO PROBLEMS

Problem: PTO (Power Take-Off) Not Engaging or Disengaging Properly

Solution:

- PTO Clutch Inspection: Check the PTO clutch for wear and adjust or replace if needed.

- PTO Shaft Examination: Inspect the PTO shaft for damage or excessive wear and replace as required.

- PTO Linkage Adjustment: Ensure the PTO control linkage is correctly adjusted and functioning properly.

STEERING ISSUES

Problem: Steering Issues – Hard or Unresponsive Steering

Solution:

- Steering Fluid Levels: Check and refill the steering fluid as necessary.

- Steering Linkage Inspection: Examine steering linkages for wear or damage and repair or replace faulty components.

- Power Steering Pump Testing: Ensure the power steering pump is operating correctly. Replace if malfunctioning.

- Steering Gearbox Check: Verify that the steering gearbox is properly adjusted and free from leaks.

FAQs

The most common issues include starting difficulties, overheating, hydraulic malfunctions, and transmission problems.

Cold weather can affect the battery, glow plugs, and fuel system, making it harder for the engine to start.

Regularly check coolant levels, clean the radiator, and ensure the thermostat and water pump are functioning properly.

Check hydraulic fluid levels, replace filters, inspect lines for leaks, and test the hydraulic pump.

It’s recommended to change the fuel filter regularly to prevent clogging and ensure smooth fuel delivery.